- HomeReturn Home

- ServicesThings We Do

- ProductsThings We Make and Sell

- PalPharma Material Handling

- VHP Enzymatic Fast DetectionCycle Development and Validation

- Mobile Electropolishing SolutionsTIG Champ and friends

- ECOsashFume Hood Auto-sash system

- Passivation TestingKoslow Kits

- Steam QualityTest Kits, Packs, and Wraps

- Sterilizer ValidationDataloggers, Kits and Software

- Environmental Data LoggersTemprecord, TAD, and more

- PartnersPeople We Work With

- InformationNews, Careers & Other Information

- Downloads

- Product BrochuresDownload PDF Versions

- ManualsDownload Product Manuals

- Software

- Certification

- Careers At TRAQuE

- Search

- Downloads

- E-ShopStuff we Sell

- All ProductsStuff we Sell

- My Cart

- Checkout

- You are here:

- Home \\

- E-Shop \\

- Passivation Testing \\

- Refill Solution No. 10

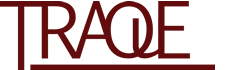

Passi-Tester 2026

Up to now, passivation verification consisted of the old-fashioned clumsy copper sulfate or ferroxyl tests or the long and complicated humidity and salt spray testing. But in selecting the Passi-Tester 2026, you've chosen a rapid response method for your verification demands. The ASME BPE 2009 and the Federal Spec QQ-P-35C approved this surface corrosion potential measurement as a method of checking passivation, so the Passivation Tester 2026 can be used with complete confidence.

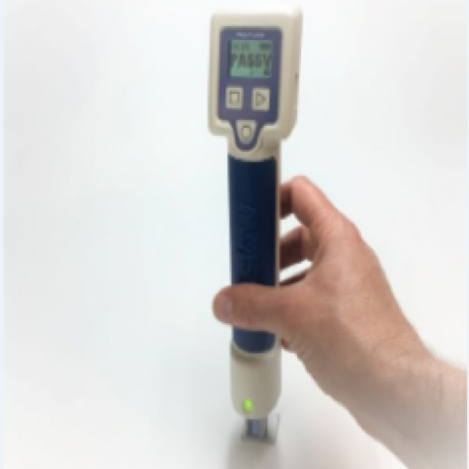

The Passi-Tester 2026 is a portable, light-weight instrument measures the corrosion tendency of the surface of stainless steels. It detects surface free iron through a galvanic process which is measured as a voltage. There is no size limitation to the test piece. A typical test, taking only 1-2 seconds, is simple: Electrical contact is made between a test piece through a moist pad. Then the sensitive Passi-Probe is pressed into the pad to complete the circuit, and the cell voltage appears on the digital meter.

This measurement can be repeated over the surface of the test part and at sensitive spots, such as seams and welds. Values for passive and non-passive readings are included in the instructions, and a standard 304 stainless steel coupon is provided for test comparison and instrument check-out. Samples reading non-passive can be passivated by running them through the passivation bath and then retested. The Passivation Tester 2026 can be used with all chromium containing stainless steels such as 300 and 400 series and the precipitation-hardened steels such as 17-4, 15-5, 17-7 and so on. Because no training is necessary, the Passivation Tester 2026 can be used successfully by non-technical personnel.

Applications:

- Check passivation of all grades of stainless steel

- Monitor passivation bath and procedure

- Detect loss of passivation in service

- Corrosion troubleshooting

- Satisfy contract requirements

- ASME BPE Approved

Features:

- Fast and easy to use

- Portable, lightweight, battery operated

- Non-destructive passivation testing

- Easy to read display

- Safe- no hazardous chemicals

- Certificate of Calibration- traceable to NIST

| Dimension (L x W x H) | 0 x 0 x 0 |

| Weight | 0 |